But Wait, What is IO-Link Anyways?

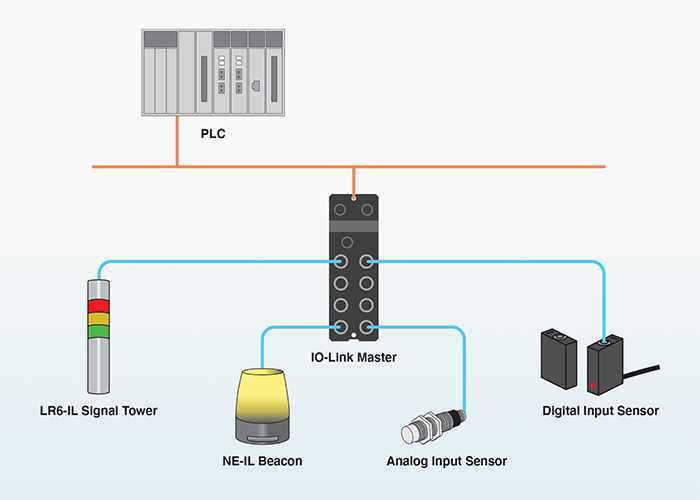

IO-Link is a bi-directional, point-to-point communication protocol, used to exchange data from field devices such as sensors and actuators that are connected to an IO-Link master. It is an open standard, meaning the connected devices can be integrated in any system or fieldbus, and its versatility enables the communication of not only the on/off states of equipment, but also statuses and detailed diagnosis information.

Standardizing factory devices into IO-Link allows for increased visibility of the overall production status, helping to enhance predicative maintenance and overall equipment effectiveness. It also eliminates the need for complex wiring or expensive interface converters, because the devices can be installed and configured directly through an IO-Link master.

Effortless Setup with IO-Link Devices

PATLITE offers a range of IO-Link compatible devices such as the NE-IL and LR6-IL series.

The NE-IL is a multi-color beacon featuring a capacitive touch sensor. The 56mm-diameter compact beacon can display 7 colors in either a continuous or flashing pattern, as well as an 88dB buzzer tone. Its rugged housing is built to withstand harsh and demanding environments, and can even be operated with wet or gloved hands. The easy-to-control and versatile functions make these indicators ideal for pick-to-light and call button applications.

The LR6-IL is the IO-Link compatible version of PATLITE’s signature LR series signal tower. It has a completely modular design, making it easy to configurate with a full range of mounting options and accessories, including clear globe LEDs, a buzzer unit, and mounting brackets and poles. Additionally, the transmitter unit of the Wireless Data Acquisition System can be attached to the signal tower, enabling you to monitor your machines remotely and in real-time while also collecting the data for further analysis.

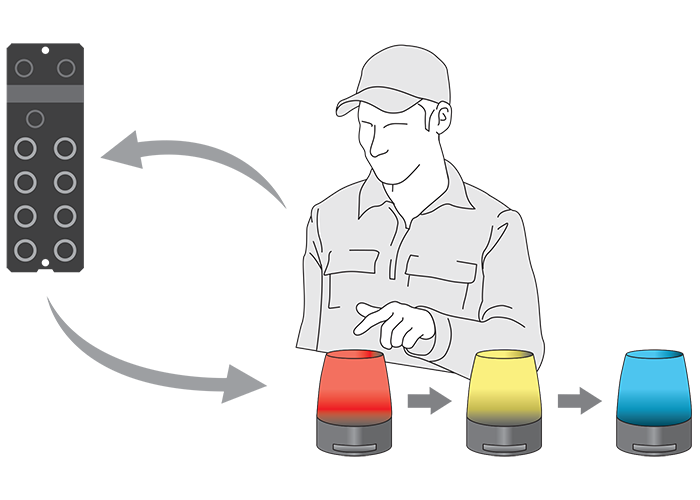

Timely Responses to Issues (NE-IL)

With 7 colors achievable on the NE-IL beacons, it is possible to color-code multiple statuses. At this busy production plant, the NE-IL beacons are being used to signal when an equipment requires maintenance. The master sends commands to activate a specific beacon to turn it red and indicate which equipment requires attention. A worker that notices the issue will touch the beacon once to turn it yellow, indicating to other workers that the issue is currently being resolved. Once maintenance is done, the worker simply touches the NE-IL again to confirm back to the master, and the beacon is back to blue to indicate that the equipment is operating normally.

Thanks to the IO-Link system, the IO-Link master acquires real-time operational data of the NE-IL beacons and other connected devices. Other information such as process data, device data, and events can also be monitored remotely, and collected for further analysis to spot trends and enhance predicative maintenance. Furthermore, whenever a new equipment is added to this production plant, additional NE-IL beacons can be connected to IO-Link quickly and efficiently, with a single M12 cable.

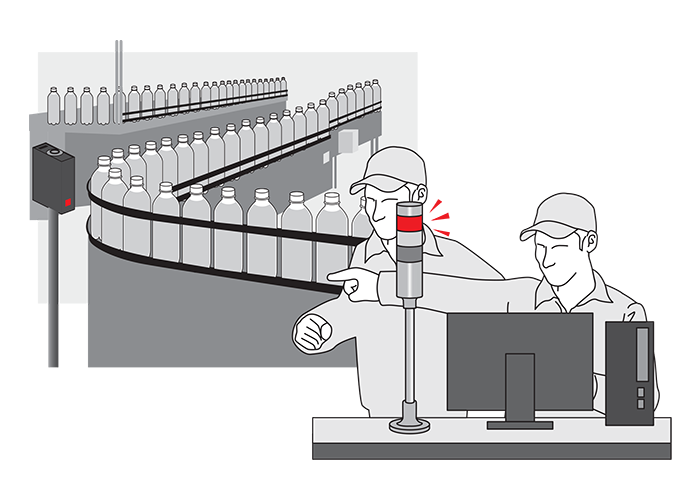

Avoid Defects and Production Delay (LR6-IL)

At this bottling facility, both a digital input sensor and the LR6-IL Signal Tower is connected to IO-Link. Whenever the sensor detects water or dust obstruction, the IO-Link master sends a command to the LR6-IL to trigger its red flashing light and buzzer. This enables operators to be notified of the issue right away, and take immediate action to avoid defective items and halts in production.

Managers at remote facilities can also acquire the real-time equipment status and operational metrics of the bottling plant. The IO-Link system also enables them to obtain not only the on/off statuses of the signal towers, but also the process data, device data, and events of the connected towers and sensors. This allows for thorough visualization of all of their equipment, helping to improve OEE and increase productivity.

New Faces at PATLITE

The PATLITE team is continuing to expand in order to better serve our customers. We are very happy to announce that we have recently welcomed 2 new employees!

|

Brad Watson

Brad is the Northeast Regional Sales Manager at PATLITE, and will work closely with customers and channel partners in his region while introducing them to PATLITE products and providing them with the best solutions for their unique applications. In his new position, Brad is eager to “work directly with partners and customers to learn about their applications, as well as how people are able to impact the world with their projects.”

|

Denisse Machuca

As the Events & Social Media Coordinator, Denisse will focus on enhancing PATLITE’s online presence across various social media platforms, as well as organize the logistics and setup of trade shows and other events. She is most excited about developing and implementing marketing campaigns with PATLITE, and is “happy to be part of an innovative marketing team to learn from and grow.”

|

|