A Signaling Solution Tailored to Your Needs

The LA6 Series is a programmable signal tower designed with a range of functions and display options, enabling flexibility for users to customize the visual and auditory alerts to be tailored to their unique application. The signal tower is designed with clear modules, each equipped with multi-color LEDs that display 21 different colors. Aside from the wide color range, the LA6 signal tower includes 11 auditory alarms, and can be programmed to display animated patterns and custom flash rates. Additionally, the LA6 towers has a 60mm diameter, making it easy to retrofit or upgrade using an existing pole or wall mount bracket.

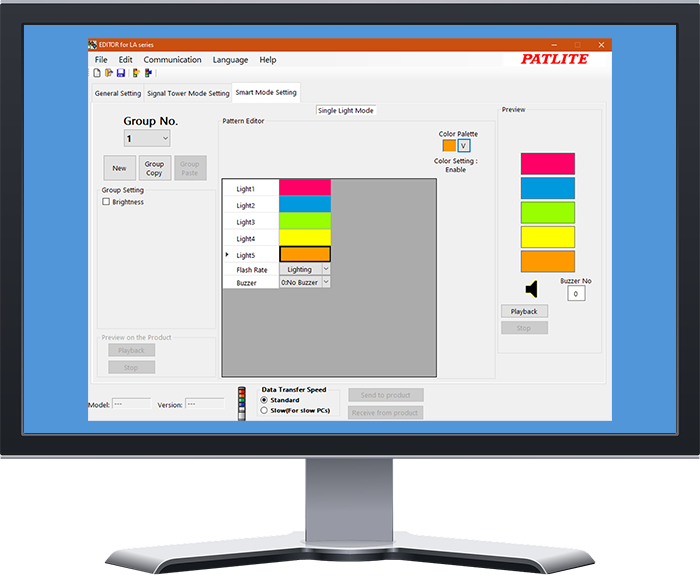

The LA6 Series can be set up to operate under 3 main Smart Modes including Time Trigger Mode, Pulse Trigger Mode, and Single-display Mode. Users can easily program the lights and sounds of their LA6 towers by using the free Editor Software, which can be downloaded from PATLITE’s website.

In Time Trigger Mode, the LA6 displays custom LED animations at preset timings. These animations are triggered initially by an input of command and run based on set timings. This function is useful in takt time applications to measure elapsed time or to count down remaining cycle time for production. The Pulse Trigger Mode displays preset animations or patterns in fixed sequences. Transitions from one pattern to another can be triggered by individual discrete inputs. This Pulse Trigger Mode can be used for applications to determine thresholds such as temperature or pressure levels. And last but not least, the Single-display Mode displays groups of preset patterns. Each group transition is triggered by an input of command. Some examples of applications that can use this Single-display Mode are status indications, error displays, and level monitoring.

The LA6 Series signal tower is available in 2 tier configurations (3-tier and 5-tier), 2 voltages (24V DC and 100-240V AC), and 2 body colors (off-white and silver). Additionally, users can select the connection method (cable or screwless terminal) and mounting method (direct or pole mount). Thanks its wide range of functions and features, the LA6 Series is suited for a multitude of applications in a wide range of industries including but not limited to automotive, aerospace, construction, packaging, processing, semiconductor, and medical industries, as well as for airports, retail stores and transportation purposes.

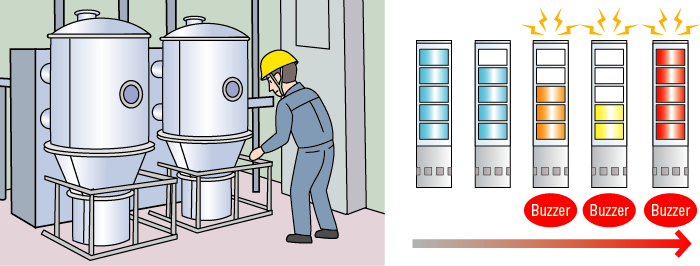

Eliminate Downtime

At this production facility, LA6 Signal Towers are used for level monitoring. Sensors track the amount of fluid inside each of their line of tanks, and the fluid levels are accurately displayed by the LA6 towers in real-time. Each of the 5 tiers on the LA6 represents how much fluid is left in the tank, and when the tank is running low and needs to be replenished, the signal tower will flash red and sound its alarm.

Before implementing this system, the factory experienced a lot of downtime when machines stopped operating due to depleted fluid and the issue remained unnoticed by the workers. After installing LA6 signal towers at every tank, workers are now able to visually recognize the amount of liquid left in each tank, and be alerted with auditory alarms when they should prepare to refill a tank before it is depleted. This has helped the facility to reduce non-operating time and increase overall work efficiency.

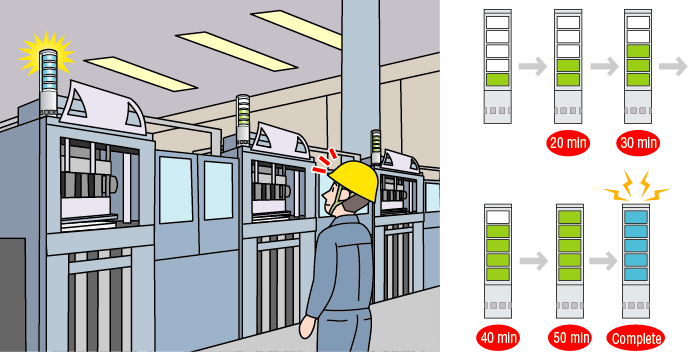

Visualize Cycle Time

At this facility, LA6 signal towers are installed at every casting machine to show its current work progress. Each of the 5 tiers of the signal tower represents the elapsed time from the start of the casting cycle until completion. All 5 tiers are illuminated when the casting is almost complete, and when fully complete and needs immediate attention by the workers, the signal tower will flash blue and sound its buzzer.

Before this system was implemented, workers had to constantly go back to each casting machine to check its status and wait for the casting task to be completed. This was a very inefficient process for operators, and was a cause of downtime if machines were unattended when the work was completed. Now, workers can visualize the elapsed time of each casting cycle, and know the exact timing of when the cycle will be completed so that they can prepare for the next casting cycle in advance.

Featured Distributor

Founded in 1955, EandM is a certified minority-owned company that brings the world’s leading automation technologies to its customers. With five West Coast locations, EandM serves original equipment manufacturers and end users in the food and beverage, forestry, municipal, automotive, pharmaceutical, oil and gas, aerospace, and consumer packaged goods industries. They offer a wide range of products for industrial software, industrial hardware, and robot solutions that maximize operational success for your workplace.

EandM ensures optimum results and highest overall customer satisfaction by providing best-in-class responsiveness, solutions expertise, in-person and online training, and 24/7 technical support. They are headquartered in Healdsburg, California and support PATLITE in the states of Washington, Oregon, and California.