PATLETTER Issue No. 27

July 16, 2024

Standardizing with IO-Link

Signaling Devices

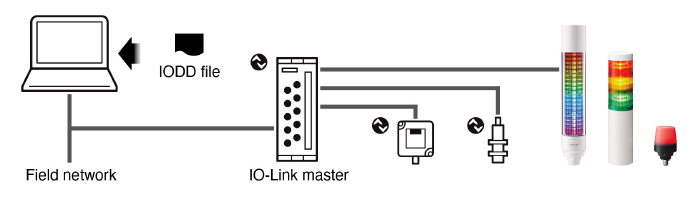

IO-Link is a bi-directional, point-to-point communication protocol, used to exchange data from field devices such as sensors and actuators that are connected to an IO-Link master. It is an open standard, meaning the connected devices can be integrated in any system or fieldbus, and its versatility enables the communication of not only the on/off states of equipment, but also statuses and detailed diagnosis information.

Standardizing factory devices into IO-Link allows for increased visibility of the overall production status, helping to enhance predictive maintenance and overall equipment effectiveness. It also eliminates the need for complex wiring or expensive interface converters, because the devices can be installed and configured directly through an IO-Link master. IO-Link also allows for easy replacement of old or damaged devices, as it automatically imports previous settings to the new device. Standardizing factory devices into IO-Link allows for increased visibility of the overall production status, helping to enhance predictive maintenance and overall equipment effectiveness. It also eliminates the need for complex wiring or expensive interface converters, because the devices can be installed and configured directly through an IO-Link master. IO-Link also allows for easy replacement of old or damaged devices, as it automatically imports previous settings to the new device.

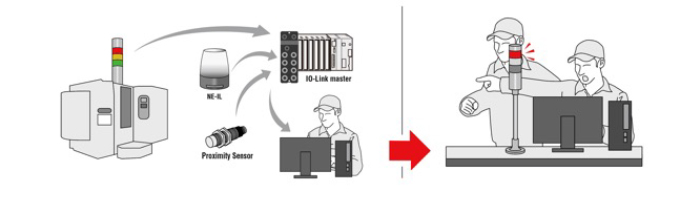

Enhance Predictive Maintenance

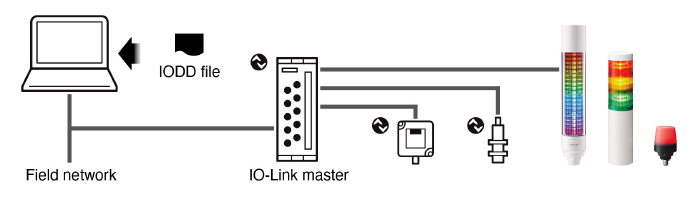

The IO-Link master acquires real-time operational data of the sensors and other devices that are connected to the system. This data can be monitored remotely, and can also be collected for further analysis.

By detecting anomalies such as water or dust obstruction, the IO-Link master can prompt the LR6-IL Signal Tower to activate its visual and audible alarms to alert personnel. This preemptive alert system helps identify potential device issues before they cause equipment malfunctions or disrupt production.

|

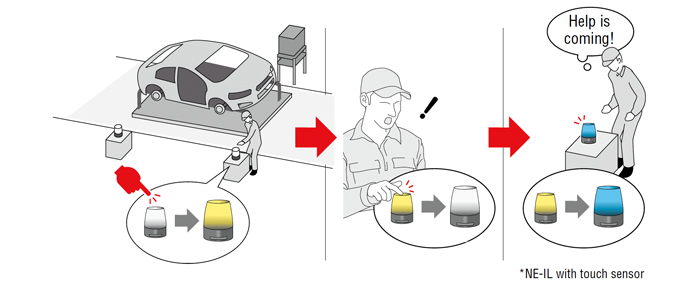

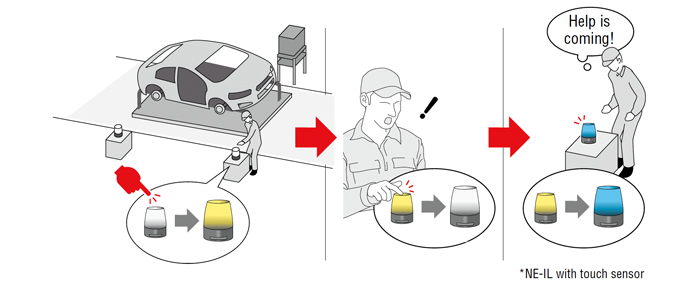

2-way Notification System

When an issue arrises, personnel at the production site touch the NE-IL to activate the visual and audible alarms of the NE-IL at the manager's site.

The manager instantly notices the alarms and determines where and what the issue is according to the illuminated color. The manager can touch the NE-IL to send notification back to the production site to indicate that help is on the way

|

Level and Temperature Monitoring

Visualization of tank level and temperature information can be achieved with preset lighting patterns. The patterns can be activate depending on the tank level. Using the level meter mode on the LB6-IL Signal Tower, easily display material replenishment timing and machine status change.

|

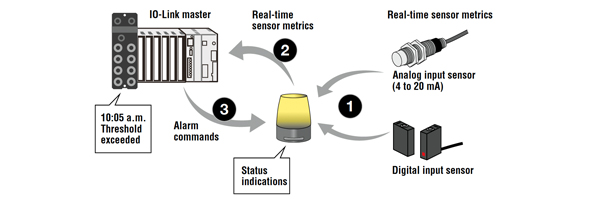

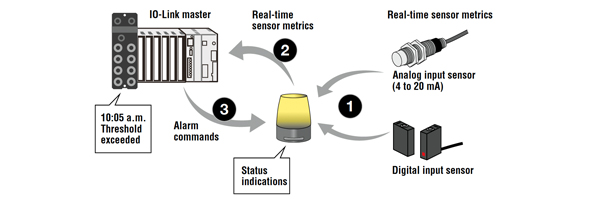

Make Devices Compatible with IO-Link

For devices that are not compatible with IO-Link, the digital/analog inputs on the NE-ILXB-M beacon can be used as an IO-Link hub. Real-time sensor metrics are sent to the beacon(1), which sends this data to the master(2). The master can then send specific commands to activate the beacon alarms(3):

|

Different IO-Link Systems and Their Masters

The performance of IO-Link masters can differ significantly, so it is important to ensure compatibility. We have evaluated the following brands and found them to work effectively with PATLITE IO-Link signaling devices:

- OMRON

- Keyence

- OptexFA

- SICK

- ifm

- Murr

- Siemens

|

|